Some would say that nicotine pouches are like a godsend. In fact, these little sachets have been transformed into what they are today through a strictly controlled manufacturing process.

How Lip Pillows are Created

The production of nicotine pouches is an automated process that takes place in factories using the latest technology. Modern equipment used includes filling machines, packaging lines and mixing machines designed to handle large quantities of product while maintaining precision.

Most manufacturers are reluctant to reveal the secrets behind the process of making their nicotine pouches. But below we describe the basic process of nicotine pouch production.

1. Extraction and purification of nicotine In order to keep nicotine pouches tobacco-free, manufacturers must isolate nicotine from the tobacco. This can be achieved in two ways: Extracting nicotine from the tobacco plant by separating it from the leaves through solvent extraction. Using molecular technology to produce synthetic nicotine in a lab by rearranging molecules to mimic tobacco leaves. The nicotine then goes through a purification process to remove impurities and ensure premium standards.

2. Mixing ingredients Next, the nicotine is converted into a powder. It is then mixed with the other ingredients mentioned above, such as sweeteners and stabilizers. The manufacturer then places everything into a white permeable bag and mixes all the ingredients together.

3. Quality Control The above two steps illustrate the basic production process of nicotine pouches. However, most manufacturers take their commitment to quality seriously and therefore include a quality control stage in their production. This extra step ensures that the pouches contain the correct amount of nicotine, the correct composition of ingredients, and that no harmful contaminants are present.

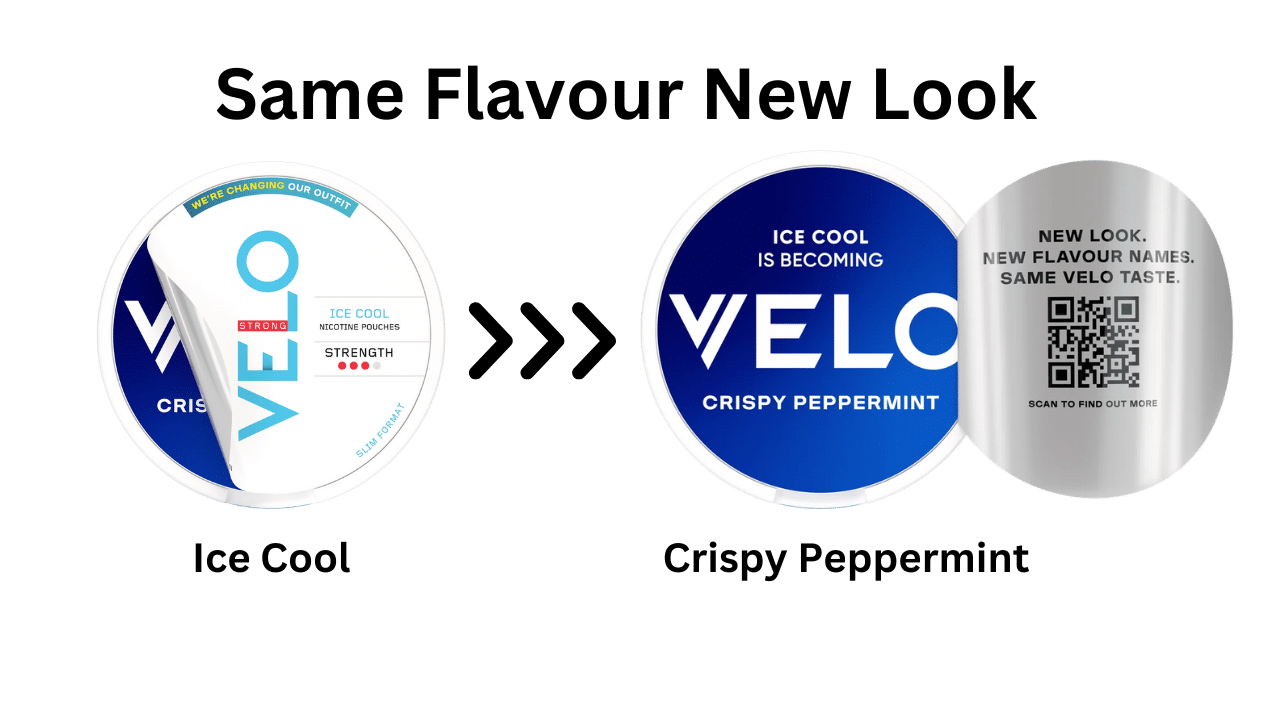

4. Packaging Finally, the pouches are sealed and placed in packaging. Manufacturers may use vacuum sealing, oxygen-absorbing packaging, nitrogen purging, or desiccants. Both the packaging and labeling processes are automated. But these steps are done with a lot of thought! Biodegradable and sustainable packaging have been on the rise recently. In addition, manufacturers are also choosing packaging that is eye-catching and practical (such as being able to store the pouches in the lid).

What are nicotine pouches made of?

The first thing you see when you see a nicotine pouch is the white, pillowy pouch. These pouches are made of plant fibers, which give them a soft outer texture that is pleasant to the mouth and releases nicotine. However, there are a variety of other ingredients in the pouch. The most important one is nicotine. Then there are the flavors that give the product its unique taste. Whether the flavor in question is a popular flavor like mint or something more unusual, the flavor is usually made up of food-grade flavors or sweeteners.

Other ingredients in nicotine pouches include:

Stabilizers. Improve flavor, maintain proper consistency and moisture, and act as a binder (such as vegetable glycerin and propylene glycol).

Fillers and texturizers. Affects nicotine release and the taste of the pouch (e.g. rubber and cellulose).

pH adjusters. Ensures nicotine is released as desired (e.g. sodium carbonate or sodium bicarbonate).

Who Manufactures Nicotine Pouches?

There are many nicotine pouch manufacturers on the market, from Swedish Match to Universal Tobacco.

These companies all follow roughly the same process, but there are subtle differences. For example, choosing between synthetic and tobacco-derived nicotine, or the choice of factory equipment.

There are also companies that have pioneered unique nicotine pouch technologies. One example is VELO’s nicotine pouches, which use bead technology (small balls of fiber filler that provide a consistent nicotine release that lasts up to an hour). This leads to further differences in the manufacturing process.

Where are nicotine pouches made?

The history of nicotine pouches can be traced back to Sweden, where they were introduced as a tobacco-free alternative to snus. Swedish Match’s ZYN was the first major brand, but many more followed. Nicotine pouches are now made all over the world, from Danish company The Ministry of Snus to Estonian brand NOIS.

There are also nicotine pouch factories in the United States and Asia. Different countries may have different health and safety regulations.